Operational Excellence Rooted in Quality and Responsibility

World Centric operations are grounded in quality, safety, and continuous innovation. Our manufacturing partners follow ISO 9001 and Food Safety for Packaging standards, with rigorous controls including automated and manual processes, regular inspections, and HACCP protocols. We work closely with suppliers to ensure our products meet the highest standards.

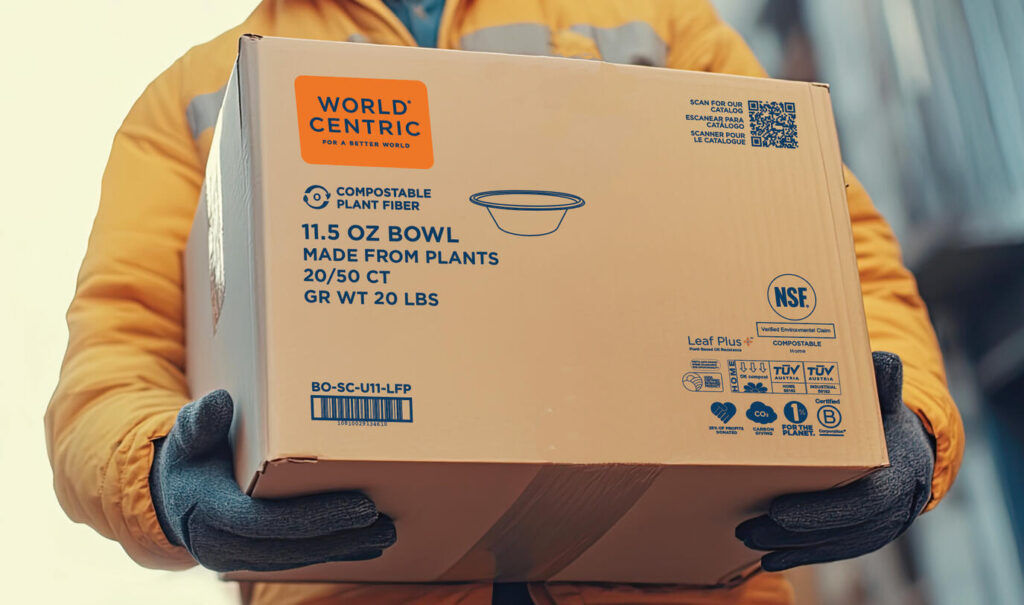

To maintain reliability, we manage a consistent supply chain with ample safety stock in our global distribution network. This allows us to avoid disruptions and stay responsive to customer needs. We’re also committed to innovation—introducing sustainable materials like FSC-certified paperboard and bamboo fiber, as well as tested solutions like fiber hot cups and our TPLA reusables line. Our domestic flexographic printing capability and inventory of blank cups enable quick-turn testing and inventory fulfillment.